Quality Inspection

Exacting Quality Inspection

Pride in Precision!

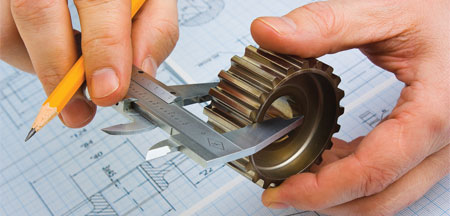

Quality inspection concerns the intensive review of a manufactured product for precise details before it is released for application. It is a vital process for ensuring a product performs as required.

Inspecting for quality is an essential step at Jake’s Inc. Every product we manufacture undergoes a rigorous start-to-finish audit including inspection of received raw material, inspection during production, and final inspection both by hand and with a coordinate measuring machine (CMM).

Reinforced by ISO 9001, UL 142 and ASME IX certification, Jake’s Inc. quality inspection confirms conformance with approved specifications, plans and codes. We verify Certified Material Test Reports (CMTR) for materials used as well.

We can furthermore serialize parts and provide full traceability on parts down to the raw material certs when requested.

If required, Jake’s Inc. quality inspection can also include non-destructive testing (NDT) including magnetic particle testing (MT), ultrasonic testing (UT) and radiographic testing (RT). NDT assesses materials to detect defects and discontinuities that might evade visual inspection. NDT exams do not damage the tested materials, thereby preserving them and ensuring they can be used for their intended application.

If required, Jake’s Inc. quality inspection can also include non-destructive testing (NDT) including magnetic particle testing (MT), ultrasonic testing (UT) and radiographic testing (RT). NDT assesses materials to detect defects and discontinuities that might evade visual inspection. NDT exams do not damage the tested materials, thereby preserving them and ensuring they can be used for their intended application.

Jake’s Inc. likewise offers close quality inspection of weldments. Jake’s Inc. employs Certified Weld Inspectors authorized by the American Welding Society to qualify processes and welders and visually accept or reject welds. Our CWIs can certify our welders and procedures to any code you may need for your project.

We also use advanced precision measuring equipment and a robust calibration program to ensure all inspection data is accurate and trustworthy. We will not release a product for use unless we are certain it has passed our strict examination. From welding to machining to metal fabrication, you have total confidence that your completed product has achieved its greatest form and function.

We don’t just aim for superior quality – we demand it of ourselves. Contact us at (630) 892-3291 today for more details about our quality inspection including our CMM and precision measuring equipment for fabrication, machining and welding.

AWS C.W.I.

AWS C.W.I. ASME Certified

ASME Certified  UL142 Certified

UL142 Certified