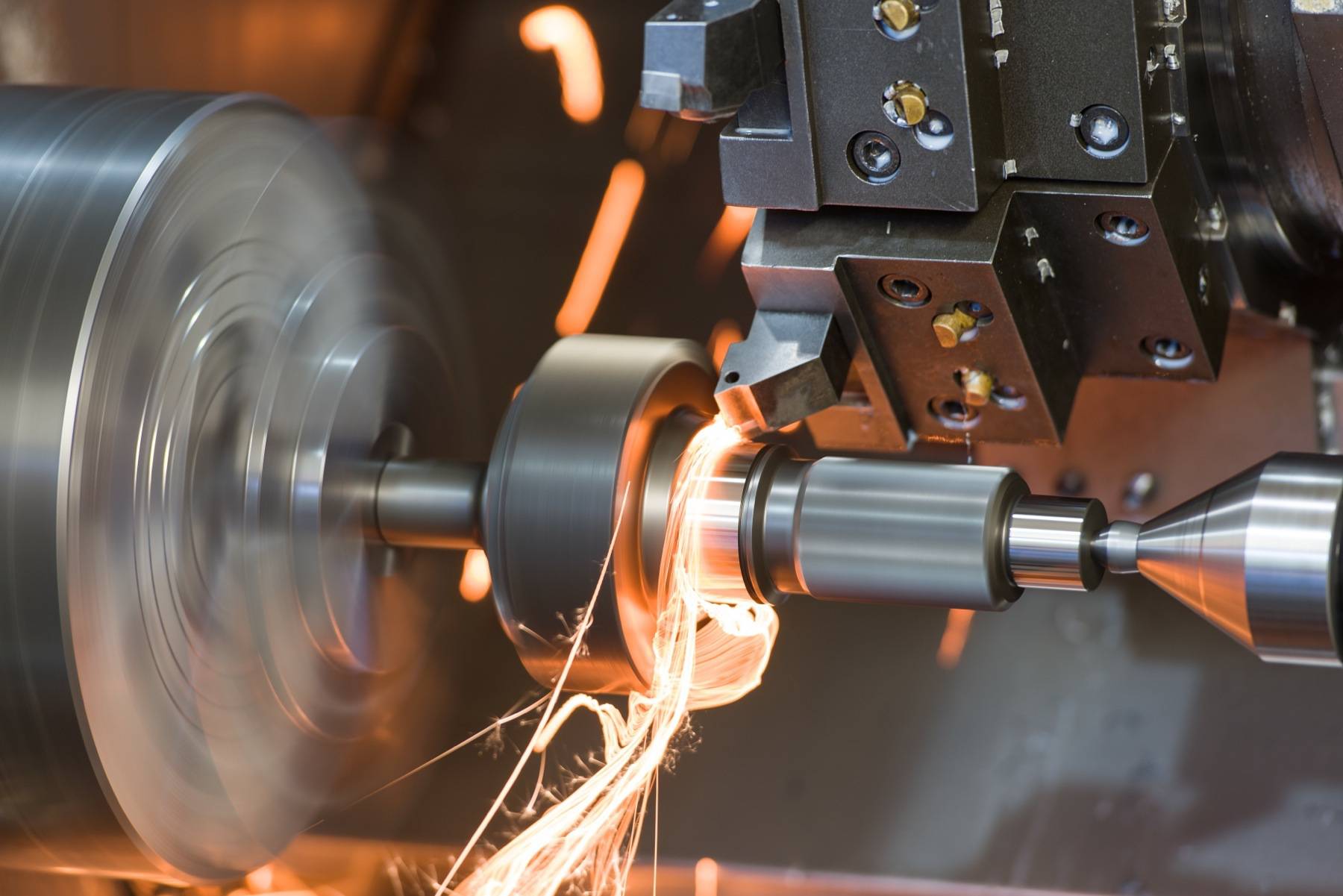

Machining

Complete Machining Abilities

Complete Machining Abilities

Pride in Precision!

With more than 100 years of total machining experience, Jake’s Inc. can perform just about any metal working you need, including turning, milling and grinding. Our broad capabilities range from jig and fixture design to complex work holding to machining exotic materials. We can also hold tight tolerances up to .0002”.

Our skill level combined with our ISO 9001 certification produces premium quality and timely delivery. Blending both classic techniques and current technology, we apply a balanced approach to machining that allows us to manufacture any number of parts ranging from prototypes to high-volume runs.

Jake’s Inc. complete machining includes:

Turning Equipment

Turning Equipment

- Fortune V-turn CNC multi-turret lathe with a bar loader for high-volume turning jobs up to 2.937” in diameter; 14.960” diameter and 32” length turning capacity LNS collet chuck and a three-jaw hydraulic chuck for larger-diameter turning

- DMG Mori NL2500Y/700 equipped with live tooling 36.4” swing 27.6” center to center 10.2” X axis travel, 3.9” Y axis travel equipped with LNS barloader

- Hitachi Seiki Hitec25S with 12’ turret style LNS bar loader for full length round/hex bars up to 2.875” diameter

- Hitachi Seiki Hitec25S 20” swing X 30” turning length

- Three Hitachi Seiki HitecTS-15 10” swing X 14” turning length

- Okuma HL 20 lathe 16” swing X15” length

- G&L lathe 22” swing X 32” length of turn

Horizontal Milling Equipment

- Toshiba 110R16: (X) 98.42”/(Y) 70.86”/(Z) 51.2”/(W) 24.8” travel; 4.33” spindle; fully programmable 360-degree turntable

- Toshiba BTD-11B: (X) 78.04”/(Y) 59.05”/(Z) 51.2”/(W) 24.8” travel; 4.33” spindle; fully programmable 360-degree turntable

- Hyundai KBN-135: (X) 118.11”/(Y)78.74”/(Z)62.992” fully programmable 360-degree turntable

Vertical Milling Equipment

- DMG mori dura vertical 1035 (X) 40.748”/(Y) 22.04”/(Z) 20.078”/rotary axis (A) 360 degree fully programmable (high speed machining)

- Hurco VMX64 (X)64”/(Y) 34”/(Z) 30” (high speed machining)

- Takumi V-15: (X) 60”/(Y) 30”/(Z) 28.346”

- Mazak MTV-655/60N (X) 60”/(Y) 30”/(Z)

- Cincinnati Arrow 1000: (X) 39.37”/(Y) 19.5”/(Z) 20”

- (3) Cincinnati Arrow 750 (X)29.53”/(Y)20”/ (Z) 20/ rotary axis (A) 360 degree fully programmable

- (2) Matsuura MC-76: (X) 29.9”/(Y) 15”/(Z) 18”

Conventional Machining Equipment

- Two Monarch manual lathes with a 16” swing 78” between centers

- Tarnow manual lathe 22”X78” gap bed 78” between centers

- Dainich manual lathe 40.15” swing over bed ways/27.55” swing over cross slide 47.24” swing over gap

- King VTL turning 52” diameter X 36” length

- (4) Bridgeport mills

- Devlieg horizontal mill

- Rockford planer mill: 148” table stroke

- Mattison rotary grinder 48” table

- Blanchard rotary grinder 36” table

- Mattison surface grinder 14” x 60” table

- Brown & Sharp surface grinder 7” x 18” table

- Peerless steel hack saw

- Professional Tool Grinding

Lifting

- 20-ton overhead hoist

- 8 ton capacity forklift

Jake’s Inc. offers sharpening and grinding that make your tooling perform like new again and give you the most life from your cutters. Our grinding machinery can sharpen almost any cutting tool from high-speed carbide drills to angle cutters to hole saws. We can alter and modify standard cutters as well.

Contact us at (630) 892-3291 today for more details about our precision machining including turning, milling and grinding.

AWS C.W.I.

AWS C.W.I. ASME Certified

ASME Certified  UL142 Certified

UL142 Certified